Cnc Information – Knowledge Levels

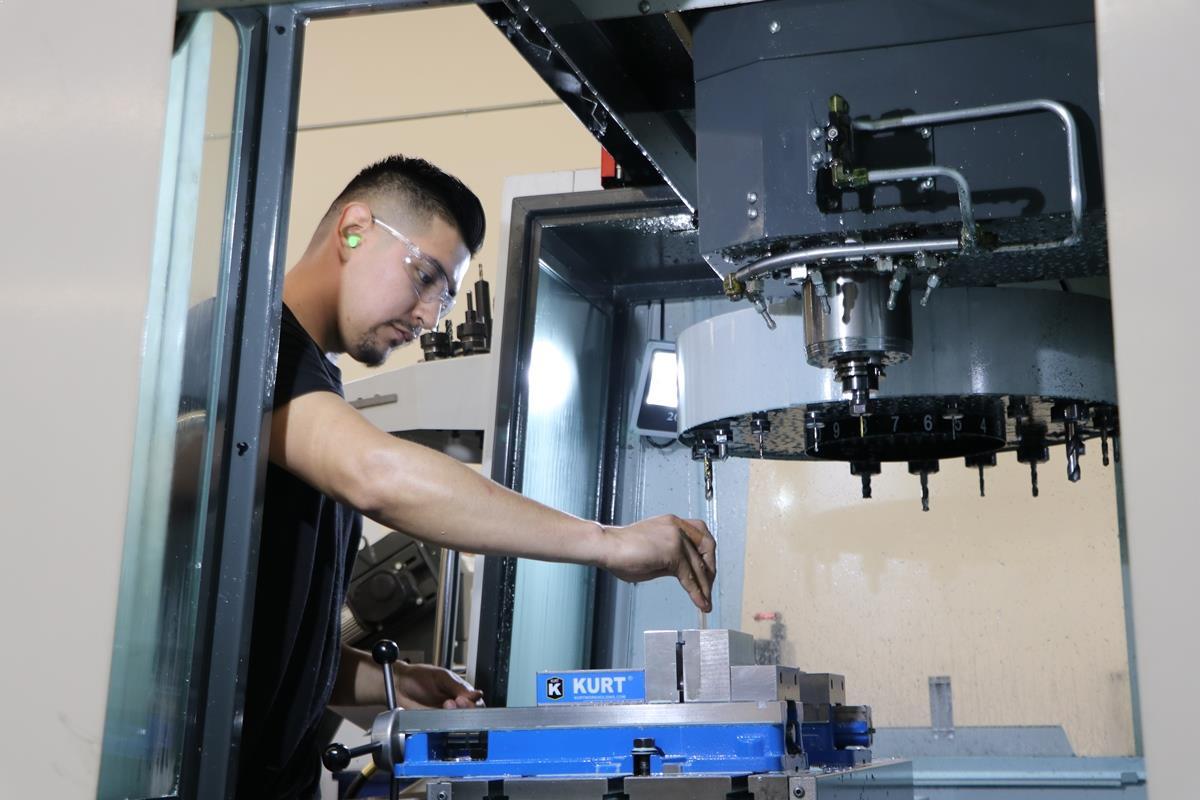

Joe Howard -Machining offers some amazing features to it when deciding on a manufacturing fashion. This method involves the removal of cloth. This means that the “start” of your product would associated with a block of material. A couple common materials for fraxel treatments are stainless steel, and wood. Particularly with CNC cutting, a range of pieces can be from these “blocks” of material. Essentially, a drill will dropped and it’ll carve, remove material, and cut bits of material offline. Other parts within machining exist too to remove material. Approach has become popular great producing small quantities of product or opportunity. It doesn’t offer the variety, or that the design capabilities of 3d printing, it might can surpass mold manufacturing in different situations.

It works jointly with woods, particular sorts of plastics and foam. Provides opened up new varieties of creativity for the personal woodworker across entire world. It comes packaged in to a set: the machine, the software, the carbide tips, and so on, make something healthy a reasonable price. Achievable even purchase refurbished Craftsman CNC routers through Sears for almost a quarter of initial company was established price.

I didn’t quite know where location this region. The Machining Chapter or Machine Controllers Chapter. It ended up here on the grounds that pendant is practically always hooked to the controller. Any pendant automatically gets a gold star from me personally. I love them. In case you use one, I guarantee you will love it. Nevertheless a true lifesaver when machining. They furnish you regarding commonly used functions about anywhere you want them. You can jog the machine to the latest location. Purchase zero your axis by using a click. May refine even take control of your machining speeds on the fly. All pendants have different and usually are associated along with a purchased getting this done.

Dirty oil is yet another common culprit to DC arcing. Comes about because the filters are full, or not fine enough to filter out the EDM sludge and grit. It must be able to filter down to a 1 micron size in order to ensure no pitting due to dirty lube.

Solid models are designed on computer system systems. They are solid in the sense that the computer knows the size of every nook and cranny in the style parts in 3D space. The designer ships data bases of each piece to the model shop, and usually a computer numerical control machine which there are plenty of kinds of is programmed and produces the pieces, looking exactly like they will when they are die cast or molded for production. There is no guessing to what it may be like when completed. Just looking at the computer rendition because it is revolved for viewing any kind of time angle eliminates any surprises when you obtain the actual part. Come to a decision find products and services you are most likely thinking.

Go for lifts built with CNC Machining and Delrin ball bearings. You have to have value to the money, so make sure these lifts are prepared with quality and precision.

The control computer features the control software loaded on face value. You start up the control software then load up the CNC Program you fashioned. When you do this, the G-Code will be visible and ready to go. Possess prep your CNC Machine and zero it out, you can start your “cycle.” A cycle is usually completing one CNC Program, which is often a machining arrangement. You will also hear the term “Cycle Time” on the professional side of CNC a a lot more. The quicker you can obtain the cycle time, the more parts you may make. And yes, that translates to more investment.

Archives

- January 2026

- December 2025

- November 2025

- October 2025

- September 2025

- August 2025

- July 2025

- June 2025

- May 2025

- April 2025

- March 2025

- February 2025

- January 2025

- December 2024

- March 2024

- February 2024

- January 2024

- December 2023

- November 2023

- October 2023

- September 2023

- August 2023

- July 2023

- June 2023

- May 2023

- April 2023

- March 2023

- February 2023

- January 2023

- December 2022

- November 2022

- October 2022

- September 2022

- August 2022

- July 2022

- June 2022

- May 2022

- April 2022

- March 2022

- February 2022

- January 2022