Brush Machines and the Rise of Smart Manufacturing

Joe Howard -

As the manufacturing industry continues to evolve with smart technologies and automation, businesses are encouraged to embrace these changes and Join Now to stay competitive, particularly with innovative tools like brush machines that enhance efficiency across multiple sectors.

As the manufacturing industry continues to evolve with smart technologies and automation, businesses are encouraged to embrace these changes and Join Now to stay competitive, particularly with innovative tools like brush machines that enhance efficiency across multiple sectors.

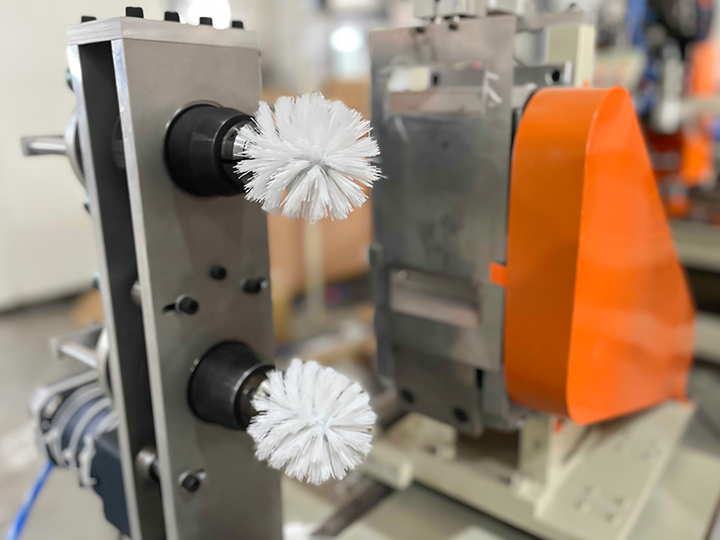

In recent years, the landscape of manufacturing has transformed dramatically, ushering in an era defined by smart technologies and automation. Among the many advancements shaping this industry, brush machines stand out as essential components in various sectors, from cleaning products to automotive applications. As the demand for precision and efficiency grows, companies that specialize in brush machine production are adapting to meet these challenges head-on.

One such leader in the field is Jiangmen Meixin Comb Brush Making Machine Manufacturing Co., Ltd. With an impressive 37 years of experience, this company has honed its expertise in creating 2-5 axis machines that reflect the latest innovations in smart manufacturing. Their commitment to quality and technology positions them at the forefront of a rapidly evolving market, emphasizing the importance of adaptability in the face of modern manufacturing demands.

Overview of Jiangmen Meixin

Jiangmen Meixin Comb Brush Making Machine Manufacturing Co., Ltd. is a well-established expert in the production of advanced brush making machines. With an impressive 37 years in the industry, the company has earned a reputation for its commitment to quality and innovation. Specializing in 2-5 axis machines, Meixin has become a leader in the market, providing cutting-edge technology to meet the evolving needs of manufacturers.

The company’s extensive experience has resulted in a robust technical foundation, allowing it to develop and refine its machinery to ensure high efficiency and precision in production. Meixin’s machines are designed to handle various aspects of brush manufacturing, catering to diverse client specifications and supporting a wide range of applications. This adaptability has positioned Jiangmen Meixin as a go-to provider for businesses seeking reliable and effective solutions.

With a focus on smart manufacturing, Jiangmen Meixin is aligning its efforts with the modern industrial landscape, emphasizing automation and connectivity in its products. The integration of smart technology not only enhances the overall functionality of their machines but also contributes to increased productivity and reduced operational costs for their clients. As the industry moves toward more intelligent manufacturing processes, Meixin is poised to play a significant role in shaping the future of brush production.

Innovations in Brush Machine Technology

The brush manufacturing industry has witnessed significant technological innovations, especially with the introduction of advanced machinery. Jiangmen Meixin Comb Brush Making Machine Manufacturing Co., Ltd. leads the charge with its state-of-the-art 2-5 axis machines that enhance precision and efficiency in production. These machines are designed to meet the diverse needs of the industry, allowing for greater customization and flexibility in brush design. The integration of automation in these machines has streamlined the manufacturing process, significantly reducing production time and labor costs.

Moreover, the evolution of smart technology within brush machines has transformed traditional manufacturing into a highly efficient and responsive system. With built-in sensors and data analytics, these machines can monitor performance in real-time, ensuring optimal operation and minimizing downtime. This real-time feedback loop contributes to higher quality products and allows manufacturers to adapt quickly to market demands and changes in specifications without sacrificing quality or consistency.

In addition to automation and smart features, the sustainability aspect of brush machine technology has also evolved. Manufacturers are now focusing on eco-friendly practices, using materials and processes that minimize waste and environmental impact. Jiangmen Meixin’s commitment to sustainability ensures that their machines not only improve productivity but also align with global efforts to promote greener manufacturing practices. These innovations position brush machine manufacturers at the forefront of both technology and environmental responsibility, shaping the future of the industry.

The Role of Automation in Manufacturing

Automation has become a cornerstone of modern manufacturing, significantly enhancing efficiency and productivity. With the advancements in technology, factories can streamline processes, reduce human error, and optimize production times. Companies like Jiangmen Meixin Comb Brush Making Machine Manufacturing Co., Ltd. exemplify how automation allows for precise control over intricate manufacturing tasks, leading to higher-quality products and faster output rates.

The implementation of 2-5 axis machines has transformed the production landscape, allowing for complex operations to be completed with minimal human intervention. This has empowered manufacturers to focus on innovation and quality rather than repetitive manual work. Jiangmen Meixin’s expertise in producing these advanced machines highlights how automation can facilitate a shift towards smart manufacturing practices, aligning with industry trends that prioritize efficiency and precision.

Furthermore, as automation technologies continue to evolve, manufacturers are increasingly harnessing data analytics and artificial intelligence. These tools not only enhance operational capabilities but also offer valuable insights into production processes. In this smart manufacturing era, companies that adapt to these changes position themselves for competitive advantage, ensuring they meet the demands of an ever-evolving market.

Benefits of Smart Manufacturing

Smart manufacturing integrates advanced technologies to create more efficient production processes. One of the primary benefits is the increase in operational efficiency. By utilizing automation and data analytics, manufacturers can optimize workflows, reduce waste, and minimize downtime. This leads to higher productivity levels and a more streamlined operation, allowing companies like Jiangmen Meixin Comb Brush Making Machine Manufacturing Co., Ltd. to produce machines that meet customer demands with precision and speed.

Another significant advantage of smart manufacturing is enhanced product quality. With smart systems in place, manufacturers can implement real-time monitoring and quality control measures throughout the production process. This not only helps in identifying defects early but also ensures that the final products meet stringent quality standards. Companies focused on the production of complex machines benefit from this as they can ensure their products are reliable and durable, which is crucial in the competitive machinery market.

Lastly, smart manufacturing allows for greater flexibility and customization. Modern consumers demand personalized products, and manufacturers must adapt to these changing needs. With smart technologies, factories can easily adjust their production lines to create different brush machines or variations without significant delays. This adaptability enables companies to respond quickly to market trends and customer preferences, giving them a competitive edge and promoting long-term growth in the industry.

Future Trends in Brush Production

As the brush production industry continues to evolve, the integration of smart manufacturing techniques is expected to play a pivotal role. Companies like Jiangmen Meixin Comb Brush Making Machine Manufacturing Co., Ltd. are leading the charge with their advanced 2-5 axis machines, which not only improve efficiency but also enhance the precision of brush making. The use of automation and intelligent manufacturing systems will minimize human error and streamline production processes, allowing for higher output and quality consistency.

Additionally, sustainability will become a crucial focus in brush production. As consumers increasingly prioritize eco-friendly products, manufacturers will need to adopt greener practices. This includes sourcing biodegradable materials and optimizing production workflows to reduce waste. Companies that can align their processes with sustainable development goals will likely benefit from a competitive edge in the market.

Finally, the future of brush production will see a greater emphasis on customization and personalization. Modern consumers are seeking products tailored to their specific needs, and advanced machinery enables manufacturers to respond quickly to these demands. The flexibility of 2-5 axis machines will allow for a wider variety of designs and applications, fostering innovation within the industry. This shift toward customization will help to create more meaningful connections between brands and their customers.

Archives

- January 2026

- December 2025

- November 2025

- October 2025

- September 2025

- August 2025

- July 2025

- June 2025

- May 2025

- April 2025

- March 2025

- February 2025

- January 2025

- December 2024

- March 2024

- February 2024

- January 2024

- December 2023

- November 2023

- October 2023

- September 2023

- August 2023

- July 2023

- June 2023

- May 2023

- April 2023

- March 2023

- February 2023

- January 2023

- December 2022

- November 2022

- October 2022

- September 2022

- August 2022

- July 2022

- June 2022

- May 2022

- April 2022

- March 2022

- February 2022

- January 2022